| Product |

|

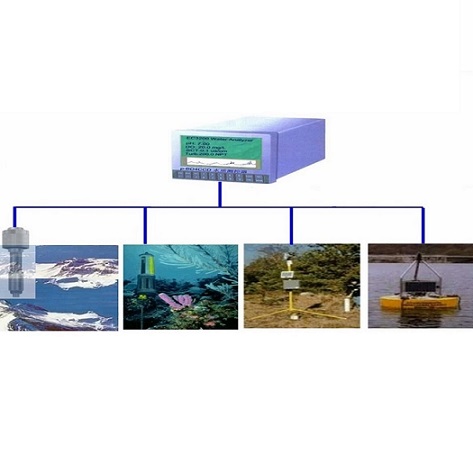

| Master Control System

|

It’s very important for industrial aquaculture to build water recirculating management and auto control system. Using this system, we can control some important water values like temperature, pH, dissolved oxygen (DO) and so on. Some water values are controlled by biological methods. For example, the nitrifying bacteria that attach and grow in the biological filtration is used to transform ammonia and nitrite-nitrogen, this process could be monitored but couldn’t be controlled exactly. Other parameters could be monitored on line and controlled exactly by physical methods as mentioned above. Temperature should be maintained within the range for optimum growth of the cultured species. Temperature could be regulated with electric immersion heaters, gas or electric heating units, heat exchangers, chillers, or heat pumps. Continuously supplying adequate amounts of dissolved oxygen (DO) to fish and biofilter in the recirculating system is essential to its proper operation. DO must be maintained above 60% of saturation of above 5 ppm. The air or pure oxygen is injected into the rearing tank water with air pump in industrial aquaculture. We can control the rotation speed of air pump to change amounts of DO, so that DO can be maintained within the optimum range. Generally speaking, fish could tolerate fry and the optimum pH range FOR biofilter bacteria is 7 to 8. So the pH range must be maintained from 7 to 8. We can control transducer, adjust valve ore electromagnetic valve to add alkaline buffers to maintain the pH within optimum range. For being supervised and controlled, these water values should be displayed and changed in computer by designing a program. This program can show data as tables and curves, the functions of this program also include how to save and print data and so on. |

| 【BACK】 |